These collaborations have been promoted by the successive CAMP (Code Assessment and Maintenace Program) agreements between CSN and the U.S. regulatory body, USNRC, which provide access to the TH simulation codes developed by said institution, i.e. RELAP5 and TRAC/P codes for PWR NPPs, TRAC/B for BWR –initially- and TRACE, currently. CAMP is the USNRC program aiming at the Verification and Validation (V&V) of these codes, as well as the international collaboration in the maintenance of the codes and the improvement of their features.

Independently of the program above, since the early 2000s, the CSN has been taking part in various NEA/OCDE programs in experimental thermalhydraulics. These international collaborations have been demanded by successive SESAR/SFEAR (The Senior Expert Group on Safety Research / Support Facilities for Existing and Advanced Reactors), reports, edited by NEA/OCDE. Such reports, among other contributions, identify key research facilities (such as thermalhydraulic experimental facilities) that are essential to maintain in order not to lose neither the knowledge nor the infrastructure required to support nuclear safety. Among the possible actions proposed by NEA/OCDE, the CSN has signed over these years different agreements concerning thermalhydraulic experimental programs carried out in the following facilities: ROSA (by JAEA, the Japanese Atomic Energy Agency), PKL (by Framatome), ATLAS (by KAERI, the South Korean organization for nuclear research), and recently RBHT (by USNRC).

Both the Programme Review Group (PRG) and the Management Board (MB) of these projects, make emphasis in the regular use of analytical activities of various kinds (e.g. pre-test analysis for the determination of the initial conditions employed in the experiments; Benchmark exercises where results from different codes are compared, or post-test analysis) to support the experimental programs. This analytical activities are also aimed at:

- Validating the safety analysis codes for phenomena involved in these experimental programs (e.g., design extension accidents).

- Studying the incidence of the scale factor and validating scaling techniques.

The synergies that exist between both lines of collaboration (i.e., CAMP and NEA) justified the unification of the respective Spanish participation within the TH simulation program CAMP-España.

USNRC CAMP PROGRAM.

The CAMP (Code Applications and Maintenance Program) Program is a international cooperation program for research in thermalhydraulics, promoted by the United States Nuclear Regulatory Commission (USNRC). The aim of this program is the verification, validation, maintenance and application of the thermalhydraulics codes RELAP5/MOD3 and TRACE. These codes are state of the art in the area of application of two-phase fuid mechanics to LWR nuclear power plants, allowing for the simulation of a large portion of the hypothetical accident scenarios, as well as nuclear tests and/or real incidents.

Along with RELAP5 and TRACE codes, CAMP agreements give access to PARCS (Purdue Advanced Reactor Core Simulator) 3D neutron kinetics code and to SNAP (Symbolic Nuclear Analysis Package), the user graphic interface for all the USNRC codes.

Under this agreement, the members must pay a fee and also must provide two in-kind contributions –or equivalent technical documents- for each year of participation, with quality enough to be published as NUREG International Agreement (NUREG/IA).

For wider dissemination of all available information and its application to the spanish NPPs, the CSN has promoted the involvement of other Spanish organizations through cooperation agreements. So far, the CAMP-Spain structure has brought together around twenty national organizations.

Activities that currently are being carried out program can be framed as follows:

- In-kind contributions. The CAMP agreement obliges its members to prepare two codes evaluation reports -or documents with an equivalent value-, that comply with a certain level quality and content as defined in the NUREG-1271. The Coordination Committee (CC) of CAMP-España analyses and approves the proposals coming from the national participants, and presents the proposals to the Technical Program Committee (TPC) of CAMP for its final analysis and approval. Such works, adequately documented and reviewed by different work groups from the national structure, are submitted to the USNRC for its review and publication as NUREG International Agreement Reports (NUREG/IA). Throughout the last phase of CAMP-Spain, the USNRC has published 41 reports which have been produced by various Spanish entities (universities, nuclear plants, CSN, engineering firms…). At the 2019 CAMP international meeting held at the premises of the UPV in Valencia, the CAMP TPC approved the current Spanish in-kind contribution set with 19 new code assessments.

- Participation in CAMP-International and CAMP-Spain specialists meeting. The TPC of CAMP organizes two specialists meetings a year. Representatives of CAMP – España have traditionally participated in such meetings, making presentations in order to update the state of the national activities, to identify anomalies and/or errors, and to describe technical contributions to the project or other code-related activities. In addition, the Coordination Committee of CAMP-España periodically organizes Technical Workshops (8 to date) which are analogous to those of the international program.

- Collaboration in the identification and solving deficiencies in the codes and all the complementary tools (manuals, auxiliary codes, etc). One of the objectives of the Program, made explicit in the CSN-USNRC agreement, covers the collaboration of the participants in the identification and resolution of problems in CAMP codes. These deficiencies must be documented in an established format.

PKL PROJECT (NEA/OECD)

During the period 2001 2020, successive international programs on experimental thermalhyraulics have been conducted in the PKL facility, (located in the Framatome site in Erlangen), sponsored by the OECD. Such programs are, to date, SETH, PKL, PKL2, PKL3 and PKL4.

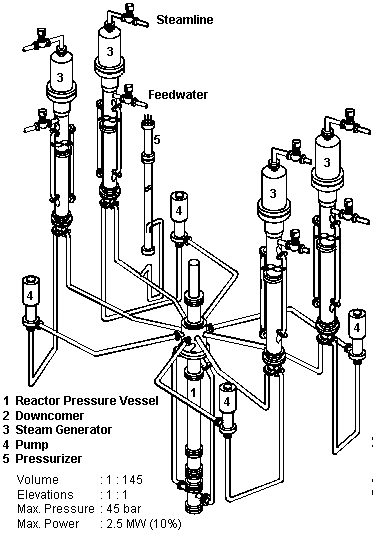

The main features of the PKL (Primärkreislauf-Versuchsanlage) experimental facility are (fig.1):

- TH integral facility that simulates a 1300 MW PWR power plant (Konvoi

- It has 4 identical loops, symmetrically placed around the vessel, and includes all of the most relevant safety and operation systems.

- Its height scale is 1:1 and its diameters scale is 1:12 (i.e, 1:145 in volumen and power).

- The refrigeration loops are identical in terms of lengths and friction factors. The vessel’s downcomer is simulated by means of an annulus and two parallel pipes.

- It also has an extensive instrumentation (1500 measure points) of temperature, pressure, monophasic and biphasic flow rate, as well as a unique instrumentation regarding the measure of local boron concentration.

Recently, a number of changes have been undertaken in the facility in order to get closer to the actual design of the PWR-W vessel:

- New bypass line in the vessel outlet

- Upper plenum internals

- Improvements in the instrumentation

- Changes in the vessel’s head and upper plenum.

The following safety-related issues have been studied so far in PKL, within these NEA/OECD programs:

- Boron dilution after a SBLOCA.

- Loss Of Heat Sink accidents during situations of outage operations, with reduced coolant inventory and with the primary system closed and open.

- Systematic study of the heat transfer mechanisms in the SG with presence of water/vapor/nitrogen mixtures.

- Cooling accident management (AM) strategies with isolated SG and empty secondary circuits.

- Fast cooling transients (steam lines breaks)

- Accident situations that require reflux-condensation maneuvers for advanced PWR designs.

- Boron precipitation after LOCA and analysis of AM strategies.

- Analysis of AM strategies for Primary cooling with formation of a bubble in the vessel’s head.

- SBLOCA transients with failures of the injection systems, analysis of AM strategies for cooling down and depressurization with SGs (counterpart to ROSA/LSTF experiment).

- Scenarios of Design Extension Conditions (DEC-A) such as long term SBO, SBLOCA with safety systems failures, and Multiple Steam Generator Tube Ruptures.

- Analysis of AM strategies for cooling down under asymmetric natural circulation (e.g. with isolated SGs) in Design Basis Accidents (DBA) or Beyond Design Basis Accidents (BDBA).

- Analysis of two-phase phenomena in LOCA situations (Counter Current Flow Limitation in horizontal pipes, reflux condensation,…)

- Intermediate-Break Loss-of-Coolant Accident

- Analysis of AM strategies in DEC-A accidents, e.g., multiple SG tube ruptures.

- Analyses of the effectiveness of passive safety systems (e.g., passive secondary injections).

The experiments conducted in PKL have contributed, up to date, to a better understanding of the complex thermalhydraulic phenomena involved in different accident scenarios, as well as to propose and evaluate accident management strategies, also providing valuable information on the safety margins available in the plants. The results of the experiments have been applied to the validation and development of thermalhydraulic simulation codes, as well.

The project joints international participants from regulatory bodies, main suppliers, engineering firms, power compaines, research organizations and universities… from a large number of countries (Germany, Belgium, Czech Republic, Finland, France, Japan, the Republic of Korea, Spain, Sweden, Switzerland, China, Hungary, The USA and Russia). On the Spanish side, besides the CSN, the “A.I.E. Centrales Nucleares Almaraz-Trillo” participates as member of the Siemens-KWU owners group.

Fig. 1 PKL Facility

ATLAS PROJECT (NEA/OECD).

In a similar way, since 2012, some international NEA/OECD programs (ATLAS1, ATLAS2 and the next ATLAS3) have been carried out at the ATLAS facility (located in the KAERI site in Daejon), with the objective of tackling various issues related to nuclear safety and to the thermalhydraulics of light water reactors.

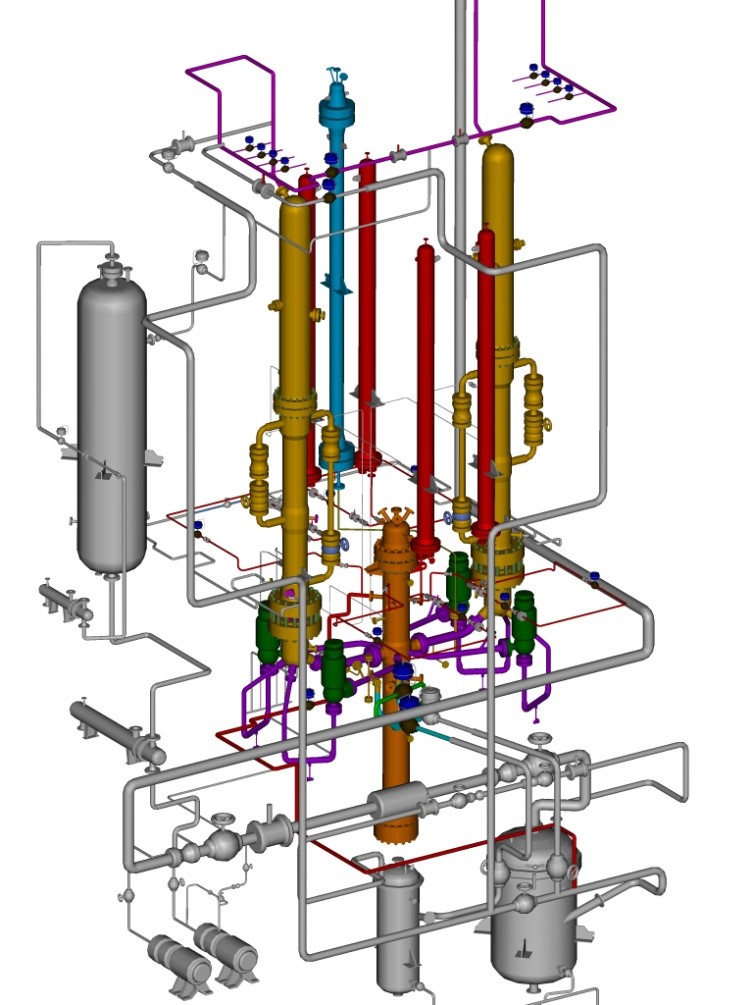

ATLAS (Advanced Thermal-Hydraulic Test Loop for Accident Simulation) is an integral test facility for advanced PWR reactors (see fig.2), simulating the APR-1400 design. Its scale factors are: 1/2 in height, 1/144 in area and 1/288 in volume.Another significant feature is that it only has two refrigeration loops, allowing to simulate an asymmetric refrigeration and a flexible distribution of the core power, being very suitable for studying the incidence of the scaling factor, specially in multidimensional phenomena.

To date, the following safety-related issues have been studied so far in ATLAS, within these NEA/OECD programs:

- Station Blackout (SBO)

- Small breaks during a SBO.

- Total Loss of Feedwater (TLOFW).

- Intermediate Break Loss-Of-Coolant Accident (IBLOCA), PZRF surge line break, Direct Vessel Injection line break.

- Design extensión condition scenarios DEC-A with multiple failures (SLB with SGTR)

- Cooling down AM strategies in low power and shutdown conditions without RHRS.

- Passive core injection.

- SBO with the Hybrid Safety Injection Tank (H-SIT)

- SBLOCA with the Passive Emergency Core Cooling System (PECCS)

- Reactor vessel head SBLOCA (counterpart experiment of the test carried out in LSTF facility).

Again, the project joints international partners from regulatory bodies, main suppliers, engineering and electrical companies, research organisations and universities from several countries (Germany, Belgium, France, Japan, the Republic of Korea, Spain, Switzerkand, China, The USA and The United Arab Emirates).

Fig. 2 ATLAS Facility

RBHT PROJECT (NEA/OECD).

A detailed knowledge of the phenomena occurring in the core reflood under various accidental scenarios, and in particular heat transfer in the fuel rods, is essential when evaluating the effectiveness of the Emergency Core Cooling System. This is a well known phenomenology, that has led to mechanistic models based on the fundamental mechanisms that govern thermalhydraulics, instead of being based on empirical correlations, that were often restricted to a specific range of applicability.

However, new fuel designs (cladding and grids materials…), current operating conditions (burnup degree, initial oxidation levels…) as well as the necessity of relaxing some conservatisms in the models, are demanding an update of the support experimental database that can lead to the production of more realistic and modern models. With this objective the USNRC has promoted, through NEA/OECD, an experimental program at the RBHT (Rod Bundle Heat Transfer) facility.

RBHT is a separate effects experimental facility (owned by Penn State University) for the analysis of the phenomena about local cooling in rods and fuel bundles during the reflood phase of LOCA accidents. It was designed and built in 1998 with the objective of obtaining data for the development and evaluation of TRACE code of the US NRC,.

This facility (see fig. 3) has been created to:

- Simulate the reflood stage in a state-of-the-art fuel element with a highly detailed distribution of termocouples, in order to obtain a precise temperature profile along the element.

- Obtain drop size measures before and after their passage trough the spacer grids, so as to provide better data on droplet breakup.

- Measure temperatures at the spacer grid in order to determine the time and conditions in which grid rewetting takes place.

- Obtain drop velocities.

- Obtain a significantly precise axial profile for steam temperature.

- Obtain detailed measurements of the pressure gradient in the fuel element.

- Carry out experiments to increase database in various heat transfer regimes.

In the past, several experiments have been conducted using constant and stationary boundary conditions, whereas there exist relatively few experiments with variable or oscillatory inlet flow, which suit better the conditions and scenarios of hypothetical accidents in a NPP.

The main objective of the RBHT project is to carry out new experiments under LOCA reflood-phase conditions, with inlet conditions which are neither stationary nor constant, and to conduct some Benchmark (BM) exercises for the simulation of the results, with an evaluation of the associated uncertainties. It is expected that, from the evaluation of the resulting data, a better and more “mechanistic” thermalhydraulic models can be obtained, i.e. models for physical processes that are based on the fundamental mechanisms that govern thermalhydraulics, instead of being based on empirical correlations, given that these are often restricted to a specific range of applicability.

Some blind BM comparing results from different codes are foreseen, in order to assess the predictive capacity of the codes, prior to the release of the experimental data. An essential part of these blind phase will be the uncertainty quantification of the codes and the models. The project is appropriate for a wide range of computational tools: thermalhydraulics system codes (RELAP5, TRACE), subchannel codes (COBRA) and CFD (FLUENT, ANSYS). The organization of some workshops allows for sharing the results from the BM, the user experiences and the sensitivity and uncertainty analyses.

Fig.3 RBHT Facility